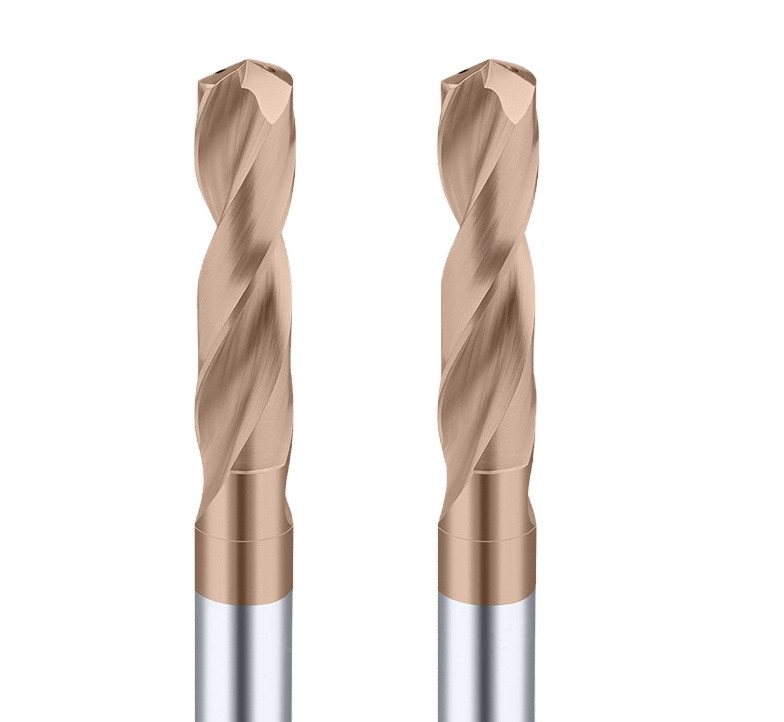

HRC55 Solid Carbide Twist Drills (3D)

Tlhaloso ea Sehlahisoa

| Diameter D | Bolelele ba Flute | Kakaretso Bolelele | Shank Diameter | Flutes |

| 1 | 8 | 38 | 3 | 2 |

| 1.1 | 12 | 42 | 3 | 2 |

| 1.2 | 12 | 42 | 3 | 2 |

| 1.3 | 12 | 42 | 3 | 2 |

| 1.4 | 12 | 42 | 3 | 2 |

| 1.5 | 12 | 42 | 3 | 2 |

| 1.6 | 12 | 42 | 3 | 2 |

| 1.7 | 12 | 42 | 3 | 2 |

| 1.8 | 12 | 42 | 3 | 2 |

| 1.9 | 12 | 42 | 3 | 2 |

| 2 | 12 | 42 | 3 | 2 |

| 2.1 | 14 | 50 | 3 | 2 |

| 2.2 | 14 | 50 | 3 | 2 |

| 2.3 | 14 | 50 | 3 | 2 |

| 2.4 | 14 | 50 | 3 | 2 |

| 2.5 | 14 | 50 | 3 | 2 |

| 2.6 | 14 | 50 | 3 | 2 |

| 2.7 | 14 | 50 | 3 | 2 |

| 2.8 | 14 | 50 | 3 | 2 |

| 2.9 | 14 | 50 | 3 | 2 |

| 3 | 14 | 50 | 3 | 2 |

| 3.1 | 20 | 60 | 4 | 2 |

| 3.2 | 20 | 60 | 4 | 2 |

| 3.3 | 20 | 60 | 4 | 2 |

| 3.4 | 20 | 60 | 4 | 2 |

| 3.5 | 20 | 60 | 4 | 2 |

| 3.6 | 20 | 60 | 4 | 2 |

| 3.7 | 20 | 60 | 4 | 2 |

| 3.8 | 20 | 60 | 4 | 2 |

| 3.9 | 20 | 60 | 4 | 2 |

| 4 | 20 | 60 | 4 | 2 |

| 4.1 | 24 | 62 | 5 | 2 |

| 4.2 | 24 | 62 | 5 | 2 |

| 4.3 | 24 | 62 | 5 | 2 |

| 4.4 | 24 | 62 | 5 | 2 |

| 4.5 | 24 | 62 | 5 | 2 |

| 4.6 | 24 | 62 | 5 | 2 |

| 4.7 | 24 | 62 | 5 | 2 |

| 4.8 | 24 | 62 | 5 | 2 |

| 4.9 | 24 | 62 | 5 | 2 |

| 5 | 24 | 62 | 5 | 2 |

| 5.1 | 28 | 66 | 6 | 2 |

| 5.2 | 28 | 66 | 6 | 2 |

| 5.3 | 28 | 66 | 6 | 2 |

| 5.4 | 28 | 66 | 6 | 2 |

| 5.5 | 28 | 66 | 6 | 2 |

| 5.6 | 28 | 66 | 6 | 2 |

| 5.7 | 28 | 66 | 6 | 2 |

| 5.8 | 28 | 66 | 6 | 2 |

| 5.9 | 28 | 66 | 6 | 2 |

| 6 | 28 | 66 | 6 | 2 |

| 6.1 | 34 | 74 | 7 | 2 |

| 6.2 | 34 | 74 | 7 | 2 |

| 6.3 | 34 | 74 | 7 | 2 |

| 6.4 | 34 | 74 | 7 | 2 |

| 6.5 | 34 | 74 | 7 | 2 |

| 6.6 | 34 | 74 | 7 | 2 |

| 6.7 | 34 | 74 | 7 | 2 |

| 6.8 | 34 | 74 | 7 | 2 |

| 6.9 | 34 | 74 | 7 | 2 |

| 7 | 34 | 74 | 7 | 2 |

| Lisebelisoa tsa Workpiece | Mefuta eohle ea likarolo tsa tšepe, likarolo tsa aluminium, li-substrates tse bonolo, joalo-joalo. | Mofuta oa letsoho | Setshoaro se otlolohileng |

| Lisebelisoa tsa lisebelisoa | Tungsten | Helix angle | 30 degree |

| Ho roala | Ee | Brand | Xinfa |

E loketse ho cheka tšepe ea tšepe ea indasteri ea likoloi le liindasteri tse ling.

Molomo oa ho itšeha o entsoeng ka leqhubu o fana ka torque e theotsoeng ea machining. Bakeng sa moralo oa margin, e ntlafatsa boleng ba lebota la lesoba le ho nepahala.

Keketseho ea matla a ho phunya lithupa ka ntlha e ntlafalitsoeng ea chisel.

Q1: Nka fuoa sampole bakeng sa tlhahlobo?

A: E, re ka tšehetsa sampole. Mohlala o tla lefisoa ka mokhoa o utloahalang ho ea ka lipuisano pakeng tsa rona.

Q2: Na nka eketsa logo ea ka mabokoseng / mabokoseng?

A: E, OEM le ODM lia fumaneha ho rona.

Q3: Melemo ea ho ba morekisi ke efe?

A: Tšireletso e khethehileng ea theolelo ea Lipapatso.

Q4: U ka laola boleng ba lihlahisoa joang?

K: E, re na le lienjineri tse itokiselitseng ho thusa bareki ba nang le mathata a tšehetso ea tekheniki, mathata afe kapa afe a ka hlahang nakong ea ho qotsa kapa ho kenya ts'ebetso, hammoho le tšehetso ea morao-rao. 100% itlhahloba pele u paka.

Q5: Na nka etela fektheri ea hau pele ho taelo?

A: Ehlile, amohela ketelo ea hau ea feme.