Litaba tsa CNC Tools

-

Mokhoa o sebetsang oa ho bala khoele, potlaka 'me u e boloke

Litlhaloso tse amanang le lipalo tse sebelisoang tlhahisong ea li-fastener: 1. Palo le mamello ea khoele e ka ntle ea khoele ea bophara ba 60 ° profile (National Standard GB 197/196) a. Palo ea litekanyo tsa motheo tsa bophara ba sekontiri Bo boholo ba motheo ba bophara ba khoele = bophara bo boholo ba khoele - pitc...Bala haholoanyane -

Litaelo tsa mananeo a CNC machining Center, haeba u sa e tsebe, tloo u ithute eona

1. Taelo ea khefutso G04X (U) _/P_ e bua ka nako ea khefu ea sesebelisoa (fepa e emisa, spindle ha e emise), 'me boleng ka mor'a aterese P kapa X ke nako ea khefu. Boleng ka mor'a Ka mohlala, G04X2.0; kapa G04X2000; khefutsa metsotsoana ea 2 G04P2000; Leha ho le joalo, litaelong tse ling tsa tsamaiso ea lesoba (joalo ka ...Bala haholoanyane -

Bakeng sa tsebo ea motheo ea lisebelisoa tsa ho itšeha, bala feela sehlooho sena

Pere e ntle e hloka sale e ntle 'me e sebelisa lisebelisoa tse tsoetseng pele tsa mochini oa CNC. Haeba ho sebelisoa lisebelisoa tse fosahetseng, ho ke ke ha e-ba le thuso! Ho khetha thepa e nepahetseng ea lisebelisoa ho na le tšusumetso e kholo bophelong ba ts'ebeletso ea lisebelisoa, ts'ebetso e sebetsang hantle, boleng ba ts'ebetso le litšenyehelo tsa ts'ebetso. Sengoliloeng sena se fana ka thuso ...Bala haholoanyane -

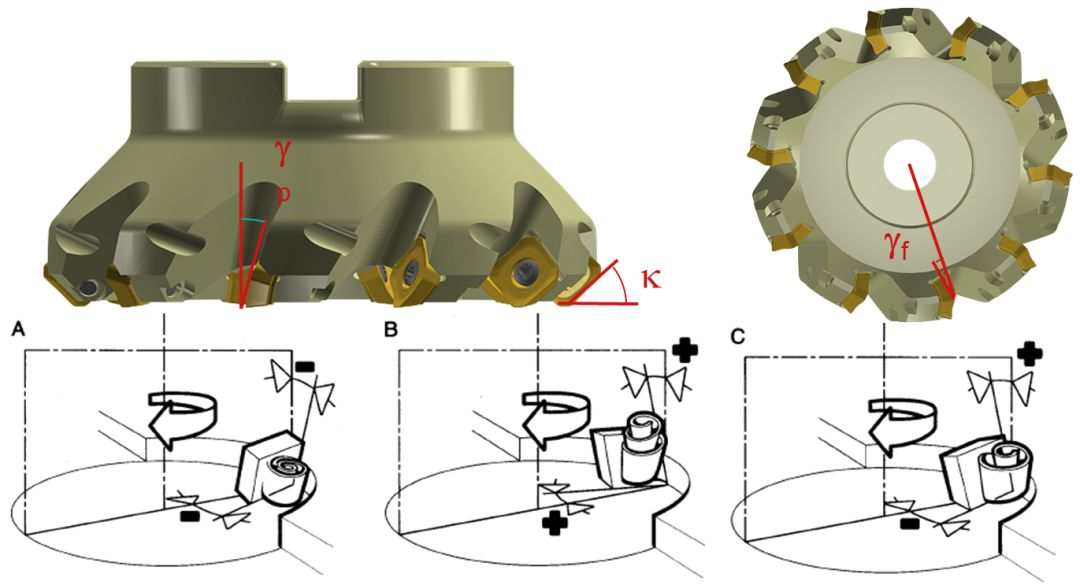

Na u hlile u utloisisa sebopeho sa li-milling cutters

Li-milling cutters li sebelisoa haholo. Na u hlile u utloisisa sebopeho sa li-griller? A re boneng ka sengoloa kajeno. 1. Li-angles tse ka sehloohong tsa li-geometric tsa li-milling cutters tsa indexable Cutter ea ho sila e na le angle e ka pele le li-angles tse peli tsa rake, e 'ngoe e bitsoa axial rake angle ha e 'ngoe e...Bala haholoanyane -

Malebela a 7 bakeng sa tlhophiso ea lisebelisoa tsa CNC tse tla tšoarella bophelo bohle

Ho beha lisebelisoa ke ts'ebetso ea mantlha le boiphihlelo ba bohlokoa ho machining a CNC. Tlas'a maemo a itseng, ho nepahala ha sesebelisoa ho ka lekanyetsa ho nepahala ha likarolo tsa mochine. Ka nako e ts'oanang, ts'ebetso ea ho seta lisebelisoa e boetse e ama ka kotloloho ts'ebetso ea mochini oa CNC. Ha hoa lekana ho tseba feela ...Bala haholoanyane -

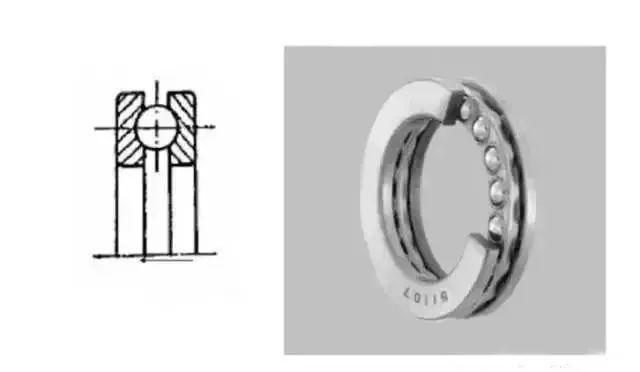

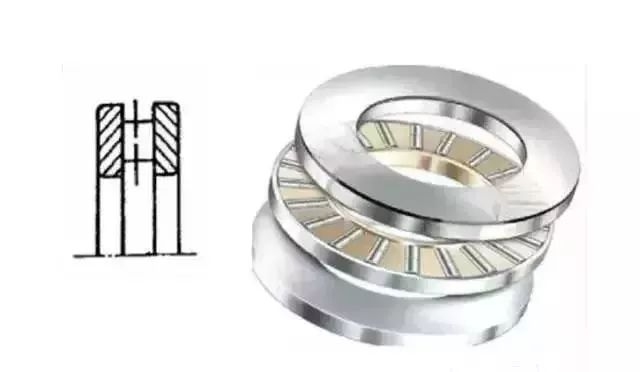

Utloisisa litšobotsi, liphapang le ts'ebeliso ea mefuta e leshome le metso e mene ea li-bearing sengoloa se le seng 01

Li-bearings ke likarolo tsa bohlokoa tsa thepa ea mechine. Mosebetsi oa eona o ka sehloohong ke ho tšehetsa 'mele o potolohang oa mochine ho fokotsa coefficient ea likhohlano tsa mojaro oa mochine nakong ea ts'ebetso ea phetisetso ea lisebelisoa. Li-bearing li arotsoe ka li-radial bearings le thrust bearings accord...Bala haholoanyane -

Utloisisa litšobotsi, liphapang le ts'ebeliso ea mefuta e leshome le metso e mene ea li-bearings sengolong se le seng 02

Li-bearings ke likarolo tsa bohlokoa tsa thepa ea mechine. Mosebetsi oa eona o ka sehloohong ke ho tšehetsa 'mele o potolohang oa mochine ho fokotsa coefficient ea likhohlano tsa mojaro oa mochine nakong ea ts'ebetso ea phetisetso ea lisebelisoa. Li-bearing li arotsoe ka li-radial bearings le thrust bearings accord...Bala haholoanyane -

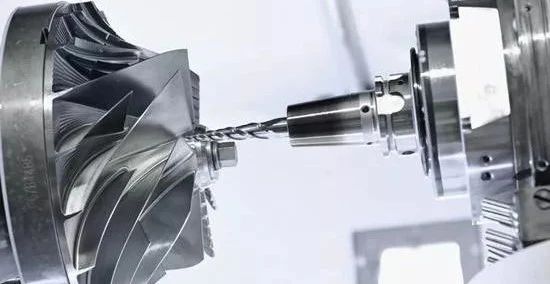

Phapang ke efe lipakeng tsa litsi tsa machining tsa li-axis tse tharo, li-axis tse nne le litsi tse hlano tsa CNC?

Lilemong tsa morao tjena, ka boqapi bo tsoelang pele le ntlafatso, litsi tsa machining tsa CNC li fumane litsi tsa machining tse tharo, li-axis tse 'ne, litsi tsa machining tse hlano, litsi tsa machining tsa CNC, joalo-joalo. Litsi tsa machining tsa CNC: li-axis tse tharo, ...Bala haholoanyane -

Mekhoa e meraro ea likhoele tsa machining setsing sa machining sa CNC

Motho e mong le e mong o na le kutloisiso e tebileng ea melemo ea ho sebelisa litsi tsa machining tsa CNC ho sebetsana le li-workpieces. Ho ntse ho na le lesira la sephiri mabapi le ts'ebetso le mananeo a litsi tsa machining tsa CNC. Kajeno Chenghui Xiaobian o tla arolelana le uena mokhoa oa ho lokisa likhoele. Ho na le mekhoa e meraro ...Bala haholoanyane -

Mokhoa oa ho khetha fepa le lebelo la reamer setsing sa machining

Khetho ea Chelete e Tsoang ho Tsoela Pele ⑴ Tumello ea ho khutlisa chelete ke botebo ba sehiloeng se boloketsoeng ho khutlisa. Hangata, tumello ea ho tsosolosa e nyenyane ho feta tumello ea ho tsosolosa kapa ho bora. Tumello e ngata haholo ea ho tsosolosa e tla eketsa khatello ea ho itšeha le ho senya mochine oa ho tsosolosa, ho fella ka ...Bala haholoanyane -

Mokhoa oa ho khetha mokelikeli oa ho itšeha, o amana le ho nepahala ha machining le bophelo ba lisebelisoa!

Ntlha ea pele, mehato e akaretsang ea ho itšeha mokelikeli Khetho ea mokelikeli oa ho itšeha e tlameha ho khethoa ka ho nahana ka lintlha tse pharaletseng tse kang lisebelisoa tsa mochine, lisebelisoa tsa ho itšeha, le theknoloji ea ho sebetsa, joalokaha ho bontšitsoe mehatong ea ho khetha mokelikeli oa ho itšeha. Pele o khetha mokelikeli oa ho itšeha ho latela ...Bala haholoanyane -

Hobaneng ha titanium alloy e le lisebelisoa tse thata ho mochini

Hobaneng re nahana hore alloy ea titanium ke ntho e thata ho e etsa mochini? Ka lebaka la ho hloka kutloisiso e tebileng ea mokhoa oa eona oa ts'ebetso le ts'ebetso. 1. Physical Phenomena of Titanium Machining Matla a sehang a ts'ebetso ea alloy ea titanium e phahame hanyane ho feta ea tšepe e nang le ...Bala haholoanyane