Litaba tsa indasteri

-

Mekhoa ea lipalo e sebelisoang ka tloaelo (khoele) bakeng sa machining ea CNC, e bonolo ebile e bonolo ho e utloisisa

1. Foromo ea lipalo bakeng sa bophara ba lesoba le ka hare la khoele ea extrusion tapping: Foromo: bophara ba leino ka ntle - 1/2 × leqhubu la leino Mohlala 1: Foromo: M3×0.5=3-(1/2×0.5)=2.75mm M6×1.0== 6-(1/2×1.0)=5.5mm Mohlala 2: Foromo: M3×0.5=3-(0.5÷2)=2.75mm M6×1.0=6-(1.0÷2)=5.5...Bala haholoanyane -

Litlhoko tsa ho nepahala bakeng sa ts'ebetso e 'ngoe le e' ngoe ea setsi sa mochini sa CNC

Precision e sebelisoa ho hlalosa botle ba sehlahisoa sa workpiece. Ke lentsoe le khethehileng bakeng sa ho hlahloba likarolo tsa geometri tsa sebaka se entsoeng ka mochine. Hape ke sesupo sa bohlokoa sa ho lekanya ts'ebetso ea litsi tsa mochini tsa CNC. Ka kakaretso, machini ...Bala haholoanyane -

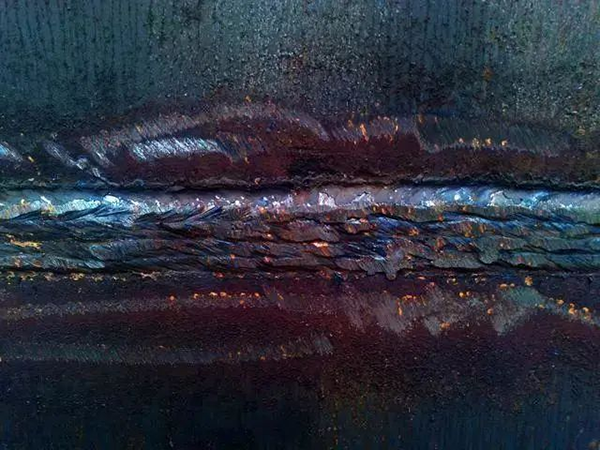

Mokhoa oa ho Weld Tšepe e Bonolo

Mokhoa oa ho cheselletsa tšepe e bonolo? Tšepe e tlaase ea carbon e na le k'habone e fokolang 'me e na le polasetiki e ntle,' me e ka lokisoa ka mefuta e sa tšoaneng ea manonyeletso le likaroloana. Nakong ea ts'ebetso ea welding, ha ho bonolo ho hlahisa har ...Bala haholoanyane -

Mathata a ho cheselletsa litšepe tse sa tšoaneng

Limetale tse sa ts'oaneng li bolela litšepe tsa likarolo tse fapaneng (tse kang aluminium, koporo, joalo-joalo) kapa li-alloys tse itseng tse entsoeng ka tšepe ea motheo e tšoanang (joaloka carbon steel, stainless steel, joalo-joalo) tse nang le phapang e khōlō linthong tsa metallurgic, tse kang 'mele. hantle...Bala haholoanyane -

Ke electrode efe e sebelisetsoang ho cheselletsa tšepe e sa hloekang

Welding ke ts'ebetso eo ho eona lisebelisoa tsa li-workpieces tse lokelang ho chesetsoa (mefuta e tšoanang kapa e fapaneng) li kopantsoe ka ho futhumatsa kapa khatello kapa ka bobeli, ka kapa ntle le lisebelisoa tsa ho tlatsa, e le hore lisebelisoa tsa li-workpieces li hokahane lipakeng tsa liathomo ho theha sebaka se sa feleng. kopanya...Bala haholoanyane -

Malebela a angle ea welding le tlhahlobo ea bofokoli ba welding

Litšitiso tse 'maloa tsa welding 01. Undercut Haeba litekanyetso tsa ts'ebetso ea welding li khethiloe ka tsela e fosahetseng kapa ts'ebetso e sa tloaeleha, li-grooves kapa li-depressions tse entsoeng ka tšepe ea motheo nakong ea welding li bitsoa undercuts. Ha o qala ho tjheseletsa, hobane ha o ...Bala haholoanyane -

Metsoalle ea ka ea welder, le tlameha ho hopola likotsi tsena

Metsoalle e ratehang ea litšepe, ts'ebetso ea ho cheselletsa motlakase eo le e etsang e ka kenyelletsa likotsi tsa mosi oa tšepe, likotsi tse kotsi tsa khase, le likotsi tsa mahlaseli a arc light nakong ea mosebetsi oa hau. Ke tlameha ho u tsebisa ka mabaka a kotsi le mehato ea thibelo! Lisebelisoa tsa welding tsa Xinfa li na le litšobotsi tsa hi ...Bala haholoanyane -

Pokello ea boiphihlelo bo sebetsang bo tsoang ho litsebi tsa welding ea argon arc

Molao-motheo oa argon arc welding Argon arc welding ke mokhoa oa ho cheseletsa o sebelisang argon ea khase ea inert e le khase e sireletsang. Litšobotsi tsa argon arc welding 1. Boleng ba weld bo phahame. Kaha argon ke khase e sa sebetseng 'me ha e sebetse ka lik'hemik'hale ka tšepe, likarolo tsa alloy li ke ke tsa ...Bala haholoanyane -

CNC lathe litsebo tsa ts'ebetso le boiphihlelo

Ka lebaka la litlhoko tse phahameng tse nepahetseng bakeng sa lihlahisoa tse entsoeng, lintho tse lokelang ho nahanoa ha ho etsoa mananeo ke: Pele, nahana ka tatellano ea ho sebetsana le likarolo: 1. Hlakola masoba pele ebe u batalatsa qetello (sena ke ho thibela ho fokotseha ha thepa nakong ea ho cheka) ; 2. Phetoho e thata ...Bala haholoanyane -

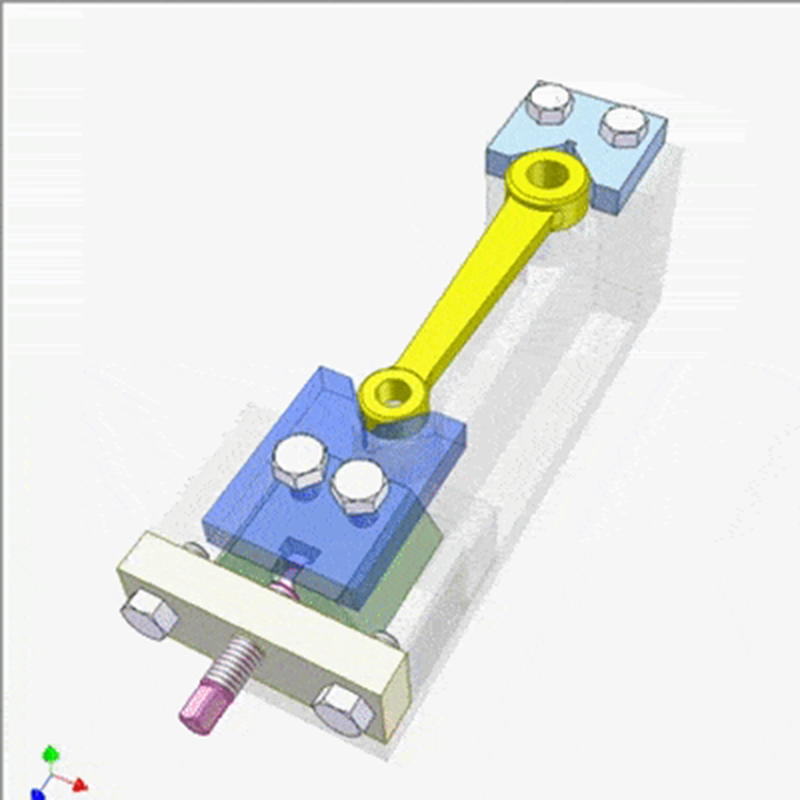

Lipopae tse 13 tse atisang ho sebelisoa ho itšebeletsa (2)

8.Self-centering fixture liboloko tse robeli tse bōpehileng joaloka V (e le 'ngoe e tsitsitse, e' ngoe e ka suthisoa) bohareng ba mosebetsi o mosehla ka longitudinally. 9.Self-centering fixture 9 The yellow running workpiece e tsepamisitsoe longitudi...Bala haholoanyane -

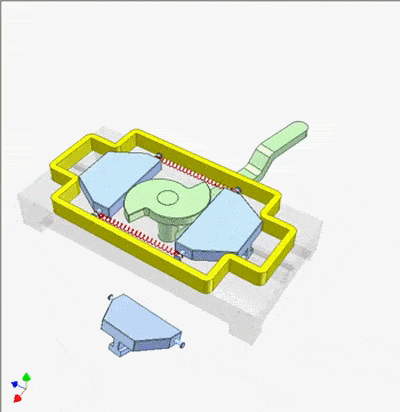

Lipopae tse 13 tse sebelisoang hangata ho its'ireletsa (1)

1. Sebopeho se ikemetseng 1 Selaete se setala se nang le mahlakore a mabeli le li-slide tse peli tse putsoa bohareng ba mosebetsi o mosehla ka thōko le ka longitudinally. 2. Sebopeho sa boithaopo 2 Likurufu tsa Orange tse nang le letsoho le letšehali le le letona ...Bala haholoanyane -

Ke lintlha life tse amang botsitso ba arc welding

Thepa ea welding ea Xinfa e na le litšobotsi tsa boleng bo holimo le theko e tlase. Bakeng sa lintlha, ka kopo etela: Baetsi ba Welding & Cutting Manufacturers - China Welding & Cutting Factory & Suppliers (xinfatools.com) Lintlha tse amang botsitso ba arc ea welding haholo-holo li kenyelletsa f...Bala haholoanyane