Litaba tsa indasteri

-

Mokhoa oa ho tjheseletsa tšepe e sa keneleng mocheso Mokhoa oa ho tjheseletsa o teng ho tla o bolella

Tšepe e thibelang mocheso e bolela tšepe e nang le botsitso ba mocheso le matla a mocheso tlas'a maemo a phahameng a mocheso. Ho tsitsa ha mocheso ho bolela bokhoni ba tšepe ho boloka botsitso ba lik'hemik'hale (ho hanyetsa kutu, ho se na oxidation) tlas'a maemo a phahameng a mocheso. Matla a mocheso r...Bala haholoanyane -

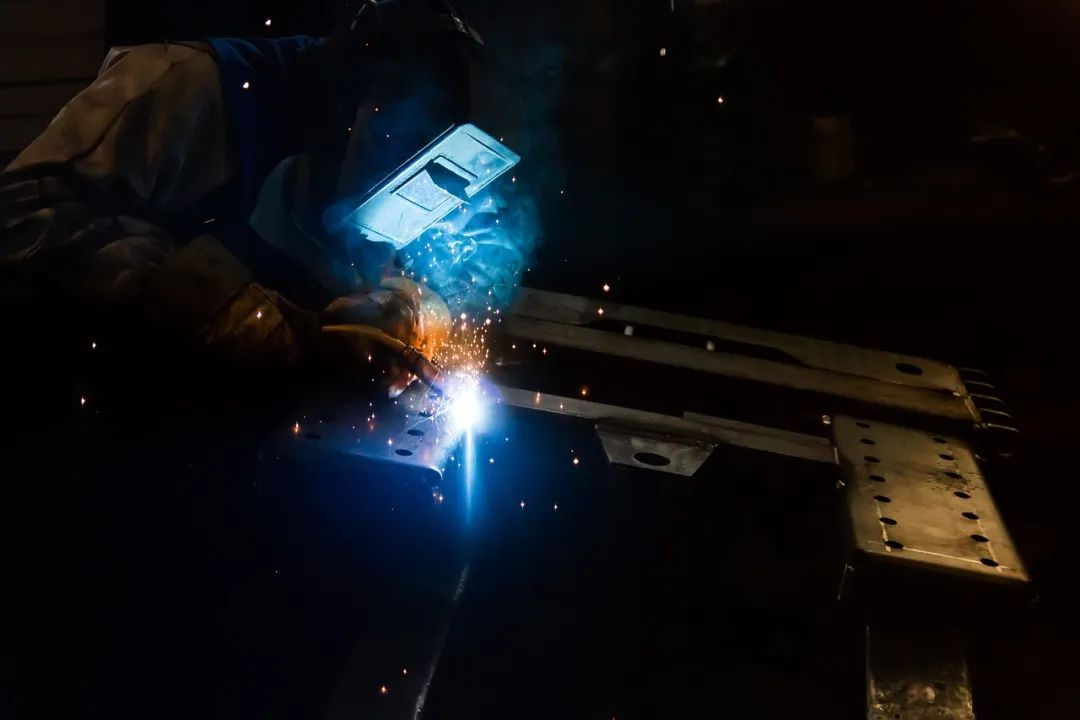

Lisosa le mehato ea thibelo ea li-pores tsa welding ho J507 electrode

Porosity ke sekoti se entsoeng ha lipululana tse ka har'a letamo le qhibilihisitsoeng li hlōleha ho tsoa nakong ea ho tiisa nakong ea ho cheselletsa. Ha o cheselletsa ka electrode ea alkaline ea J507, ho na le li-pores tse ngata tsa nitrogen, li-hydrogen pores le CO pores. Sebaka se bataletseng sa welding se na le li-pores tse ngata ho feta maemo a mang; ho na le...Bala haholoanyane -

Bakeng sa tsebo ea motheo ea lisebelisoa tsa ho itšeha, bala feela sehlooho sena

Pere e ntle e hloka sale e ntle 'me e sebelisa lisebelisoa tse tsoetseng pele tsa mochini oa CNC. Haeba ho sebelisoa lisebelisoa tse fosahetseng, ho ke ke ha e-ba le thuso! Ho khetha thepa e nepahetseng ea lisebelisoa ho na le tšusumetso e kholo bophelong ba ts'ebeletso ea lisebelisoa, ts'ebetso e sebetsang hantle, boleng ba ts'ebetso le litšenyehelo tsa ts'ebetso. Sengoliloeng sena se fana ka thuso ...Bala haholoanyane -

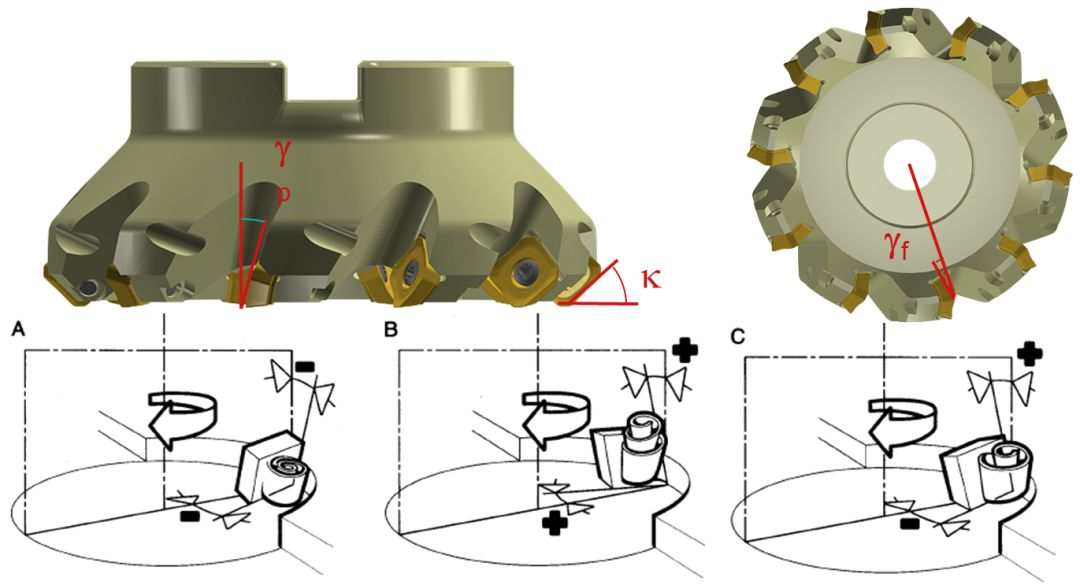

Na u hlile u utloisisa sebopeho sa li-milling cutters

Li-milling cutters li sebelisoa haholo. Na u hlile u utloisisa sebopeho sa li-griller? A re boneng ka sengoloa kajeno. 1. Li-angles tse ka sehloohong tsa li-geometric tsa li-milling cutters tsa indexable Cutter ea ho sila e na le angle e ka pele le li-angles tse peli tsa rake, e 'ngoe e bitsoa axial rake angle ha e 'ngoe e...Bala haholoanyane -

Malebela a 7 bakeng sa tlhophiso ea lisebelisoa tsa CNC tse tla tšoarella bophelo bohle

Ho beha lisebelisoa ke ts'ebetso ea mantlha le boiphihlelo ba bohlokoa ho machining a CNC. Tlas'a maemo a itseng, ho nepahala ha sesebelisoa ho ka lekanyetsa ho nepahala ha likarolo tsa mochine. Ka nako e ts'oanang, ts'ebetso ea ho seta lisebelisoa e boetse e ama ka kotloloho ts'ebetso ea mochini oa CNC. Ha hoa lekana ho tseba feela ...Bala haholoanyane -

Phapang lipakeng tsa manonyeletso a tjheseletsang a tsitsitseng, manonyeletso a tjheseletsa a potolohang le manonyeletso a tjheseletsang a tjheseletsang dipeipi.

Ho sa tsotellehe hore na motsoako oa welding o hokae, ha e le hantle ke pokello ea phihlelo ea welding. Bakeng sa ba qalang, maemo a bonolo ke boikoetliso ba mantlha, ho qala ka ho potoloha ebe o fetela pele ho boikoetliso ba maemo a tsitsitseng. Motsoalle oa welding e tsitsitseng ka pipeline welding ke rotational weldi...Bala haholoanyane -

Tlhaloso e qaqileng ea mokhoa oa ho cheselletsa letheba

01.Tlhaloso e khuts'oane ea Spot welding ke mokhoa oa ho tjheseletsa oa ho hanyetsa oo likarolo tsa welding li bokelloang ka li-lap joints ebe li hatelloa pakeng tsa li-electrode tse peli, ho sebelisa mocheso oa ho hanyetsa ho qhibiliha tšepe ea motheo ho etsa manonyeletso a solder. Spot welding e sebelisoa haholo-holo likarolong tse latelang: 1. Overlap of thin pl...Bala haholoanyane -

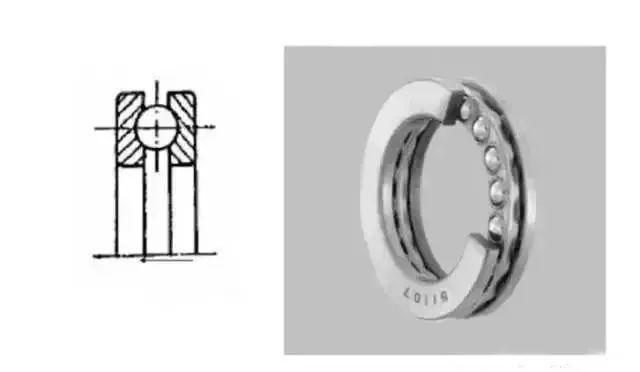

Utloisisa litšobotsi, liphapang le ts'ebeliso ea mefuta e leshome le metso e mene ea li-bearing sengoloa se le seng 01

Li-bearings ke likarolo tsa bohlokoa tsa thepa ea mechine. Mosebetsi oa eona o ka sehloohong ke ho tšehetsa 'mele o potolohang oa mochine ho fokotsa coefficient ea likhohlano tsa mojaro oa mochine nakong ea ts'ebetso ea phetisetso ea lisebelisoa. Li-bearing li arotsoe ka li-radial bearings le thrust bearings accord...Bala haholoanyane -

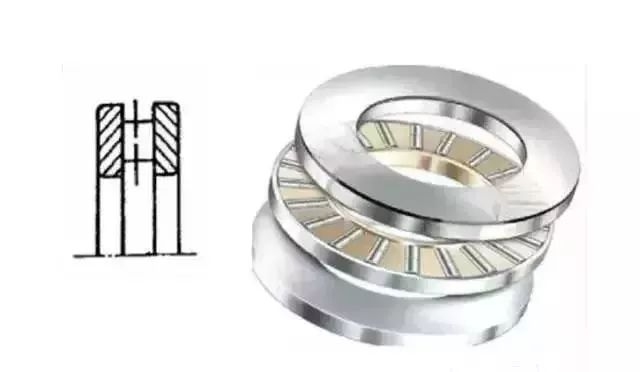

Utloisisa litšobotsi, liphapang le ts'ebeliso ea mefuta e leshome le metso e mene ea li-bearings sengolong se le seng 02

Li-bearings ke likarolo tsa bohlokoa tsa thepa ea mechine. Mosebetsi oa eona o ka sehloohong ke ho tšehetsa 'mele o potolohang oa mochine ho fokotsa coefficient ea likhohlano tsa mojaro oa mochine nakong ea ts'ebetso ea phetisetso ea lisebelisoa. Li-bearing li arotsoe ka li-radial bearings le thrust bearings accord...Bala haholoanyane -

Phapang ke efe lipakeng tsa litsi tsa machining tsa li-axis tse tharo, li-axis tse nne le litsi tse hlano tsa CNC?

Lilemong tsa morao tjena, ka boqapi bo tsoelang pele le ntlafatso, litsi tsa machining tsa CNC li fumane litsi tsa machining tse tharo, li-axis tse 'ne, litsi tsa machining tse hlano, litsi tsa machining tsa CNC, joalo-joalo. Litsi tsa machining tsa CNC: li-axis tse tharo, ...Bala haholoanyane -

Kamora ho sebetsa lilemo tse ngata hakana, nke ke ka khona ho hlalosa hantle phapang lipakeng tsa CO2, MIGMAG le pulsed MIGMAG!

Khopolo le ho hlophisoa ha tšepe ea tšepe ea arc welding Mokhoa oa ho tjheseletsa oa arc o sebelisang electrode e qhibilihisitsoeng, khase e ka ntle e le setsi sa arc, 'me e sireletsa marotholi a tšepe, letamo la ho tjheseletsa le tšepe e phahameng ea mocheso sebakeng sa welding e bitsoa molten electrode gas shielded arc. tjheseletsa. Ho latela...Bala haholoanyane -

Ke mekhoa efe ea tlhahlobo e sa senyeheng ea li-welds, Phapang ke efe

Teko e sa senyeheng ke ts'ebeliso ea lisebelisoa tsa acoustic, optical, makenete le motlakase, ntle le ho senya kapa ho ama ts'ebeliso ea ntho e tlas'a motheo oa ts'ebetso ea ntho e lokelang ho hlahlojoa, ho bona boteng ba bofokoli kapa inhomogeneities nthong eo. ho hlahlojoa, ...Bala haholoanyane